Steinbichler Comet 5

That's a system ideal for product development and quality control.

By scanning the surfaces of a real model, it creates STL mesh, which must be properly treated with apropriate software (geomagic, powershape, etc) converting the STL in surfaces. This task is a little bit boring and might take long.

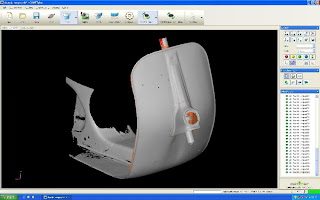

This picture shows the surfaces being build while I'm taking shots. The software allows to paste each shot in order to link each other until form a unique mesh.

Only this example can have between 50 to 100 shots accoding to the accuracy that we desire.

More technical information about the 3D Digitizer go to the site:

http://www.steinbichler.com/en/main/comet_5.htm